| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TOPCBS |

| Model Number : | BIB and test Boards |

| Certification : | UL94V0 |

| Price : | Negotiation |

| Payment Terms : | T/T |

| Supply Ability : | 10000unit per month |

| Delivery Time : | 10-14working days |

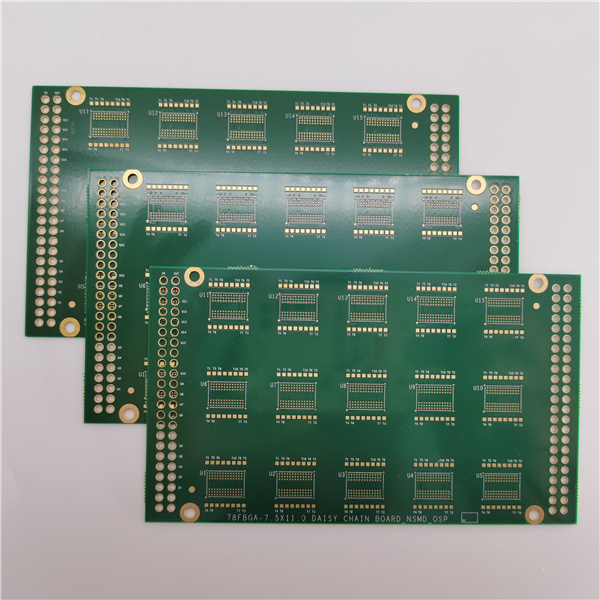

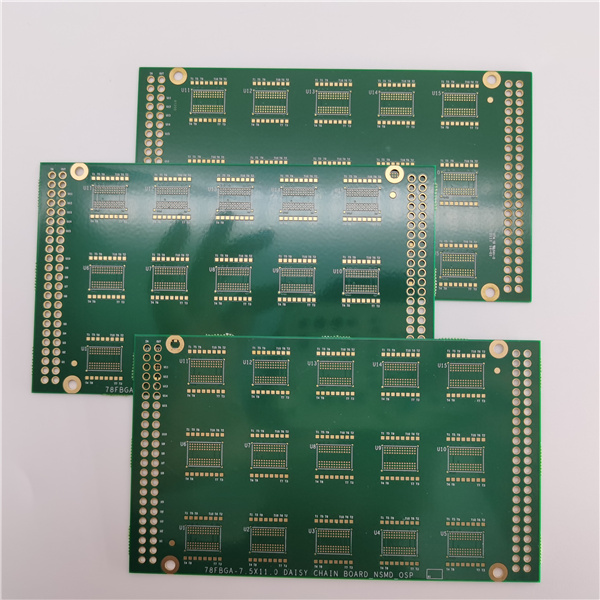

12Layer HDI PCBs for Burn in boards and semiconductor Test boards / thin board

Burn-in is the testing of components on a PCB to uncover early failures and establish load capacity.

This is done by running a power supply through the electronics at an elevated temperature, often its maximum-specified capacity. This process is conducted continuously for 48 to 168 hours, with the goal being to snuff out any latent defects triggered by the conditions of the test.

These defects – called infant mortalities – are bad for business. Electronics have a higher failure rate at the beginning of their life cycle, leveling out in the middle and rising again as they reach the end of the life cycle. If a PCB with an infant mortality failure like this were to make its way into military or medical equipment, it could result in a potentially serious failure

Burn-in testing reduces the number of infant mortlity rates by triggering them through this testing, resulting in a more reliable batch of electronics for the OEM, the trade-off being a smaller yield and potentially reduced product lifespan. The data collected through this process can in turn help engineers understand what caused the defects and modify the design to improve product reliability before it even hits burn-in.

1 . Descriptions:

What is a BIB ?

A burn-in board is a printed circuit board that is used in the burn-in process. The components added to the board are stressed using extreme heat to highlight any failures. Once the stress tests have been completed engineers will analyse the results to make sure everything is working within the correct parameters.

2 . Specifications:

| Name | 8Layer HDI PCBs for Burn in boards and semiconductor Test boards |

| Number of Layers | 8 |

| Quality Grade | IPC 6012 Class 2,IPC 6012 Class 3 |

| Material | IT180 |

| Thickness | 0.8mm |

| Min Track/Spacing | 75um/75um |

| Min Hole Size | Laser 75um |

| Solder Mask | Green |

| Silkscreen | White |

| Surface Finish | Immersion gold + OSP |

| Finished Copper | 12um |

| Production time | 10-21 working days |

| Lead time | 2-3 days |

|