| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TOPCBS |

| Model Number : | High TG CCL 8Layer main board using in electric power |

| Certification : | UL94V0 |

| Price : | Negotiation |

| Payment Terms : | T/T |

| Supply Ability : | 10000unit per month |

| Delivery Time : | 10-14working days |

8Layer Immersion Gold Finished Multilayer Printed Circuit Prototype PCB Board

A Multilayer PCB is a printed circuit board that has more than 2 layers, unlike a double sided PCB or a 2 layer PCB board, which only has two conductive layers of material. All multilayer PCB’s must have at least three layers of conductive material.

A Multilayer PCB is much more complex than a double-sided PCB design and can have any number of layers - choose from 4 layer PCBs to 6 layer PCBs, 8 layers or even up to 64 layers. Multilayer PCB’s are laminated and glued together with layers of heat protection insulation between them.

Multilayer boards provide both high capacity and speed in a smaller footprint by their innate electrical properties. Connectors that are required for multiple separate PCBs are reduced or eliminated, simplifying construction and further reducing weight.

Multilayer board thickness is 370 mil and the finished copper weight inner layer 15 oz/ outer layer 15oz. The line width & space of a multilayer PCB is a minimum 3mil/3mi and a minimum drill size cnc 4 mil. The minimum drill size laser drill of our multilayer PCBs is 3 mil, with an aspect ratio of 18:01 and a maximum board size of 43”x26”. The minimum core thickness for Pure's multilayer PCBs is 2mil and the impedance control tolerance +/- 5%.

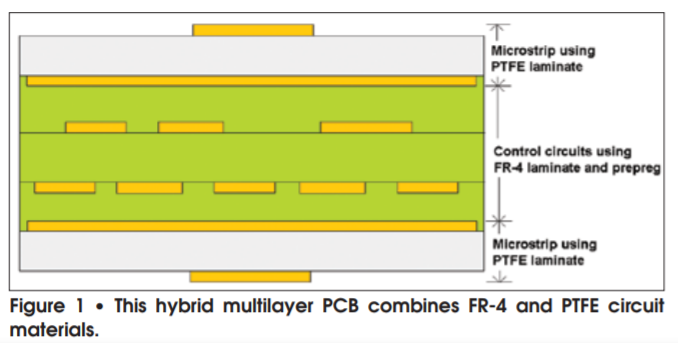

Hybrid multilayer PCBs often make use of circuit materials with very different values of dielectric constant (Dk). For example, some multilayer antenna circuits may consist of a low-Dk circuit material as the outside layer for radiating elements, a moderate-Dk circuit material internally for a stripline antenna feed line, and a high-Dk material for an internal layer for filter circuitry. The different Dk materials are often based on different resin systems. The outer, low-Dk layer may be PTFE material while the inner, moderateDk circuit layer is formed on a ceramic-filled hydrocarbon-based laminate. The bonding materials could be based on either type of material, although hydrocarbonbased bonding materials are more often used for their ease of circuit fabrication.

2 . Specifications:

| Name | 8Layer main board / immersion gold |

| Number of Layers | 8 |

| Quality Grade | IPC 6012 Class 2,IPC 6012 Class 3 |

| Material | IT180A + Rogers4350B + Copper Block |

| Thickness | 2.0mm |

| Min Track/Spacing | 100um/100um |

| Min drill Size | 0.2mm |

| Solder Mask | Green |

| Silkscreen | White |

| Surface Finish | Immersion gold |

| Finished Copper | 1OZ |

| Aspect ratio | 8:1 |

3. Product application

Printed circuit boards (PCBs) with characteristic impedance control are widely used in high frequency circuit. PCB's that mixed high frequency material can reduce signal loss at high frequencies and meet the development needs of communication technology.

It is mainly used in the infrastructure field of transmission cores including WDM/OTN end-to-end intelligent optical transmission platform, MSTP/multi-service transmission platform, microwave fusion transmission radio frequency, data communication system platform, and other information communication industries.

|